Do Slaughterhouse Machines Affect Meat Quality?

Automated slaughter improves meat quality after slaughter by enhancing texture, carcass quality, and ensuring precision in processing.

13 June, 09:06

When it comes to meat production, quality is everything. Many people wonder: Do slaughterhouse machines affect meat quality?

The answer is yes — but in a good way, when used correctly. Advances in automated slaughter technology have brought precision and consistency that can actually improve meat quality after slaughter.

How Machines Influence Meat Quality After Slaughter

The technological advancements in meat processing have revolutionized post-slaughter handling, directly impacting final product quality. The effect of machines on meat texture and overall quality is significant. Modern abattoirs employ sophisticated equipment throughout the harvesting process, from the moment animals enter the facility until packaging. Precise stunning, bleeding, and processing help minimize stress on the animal, which is crucial. Research consistently demonstrates that elevated pre-slaughter stress hormones negatively affect meat development during rigor mortis.

Stress can negatively impact factors like tenderness, color, and shelf life. When animals experience excessive stress, glycogen reserves deplete rapidly, resulting in higher ultimate pH values that produce dark, firm, and dry meat conditions. Automated systems ensure these steps happen quickly and humanely, leading to better carcass quality factors overall. The consistent application of mechanical chilling systems further enhances product uniformity by controlling temperature decline rates, allowing for optimal enzymatic tenderization while preventing bacterial proliferation that would otherwise compromise safety and sensory attributes.

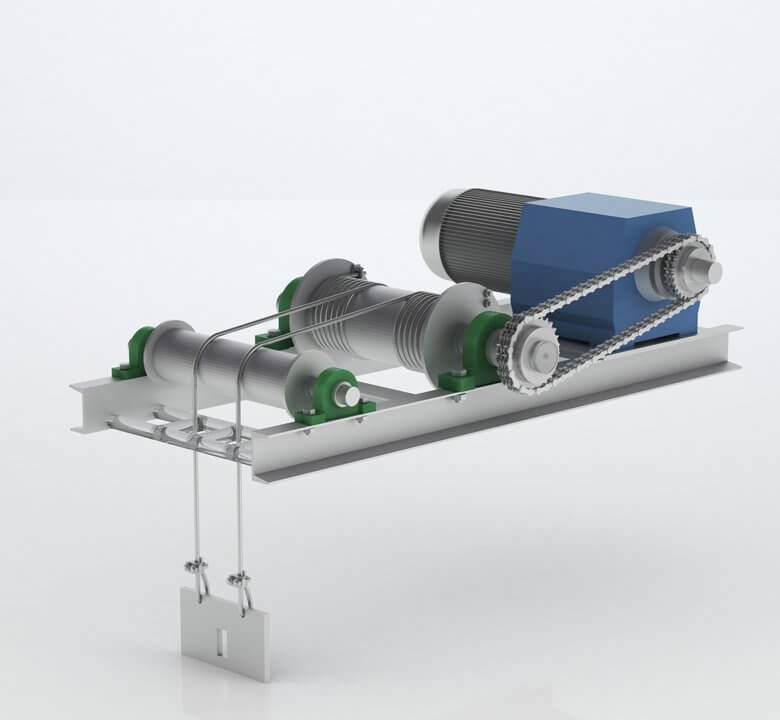

See also: carcass splitting

Automated Slaughter and Meat Grade

Automated slaughter has revolutionized the meat industry, transforming traditional processing into a precision-driven operation. Automated slaughter doesn't just speed up production; it standardizes it. Modern facilities employ sophisticated machinery that handles everything from stunning to sectioning, reducing human intervention while maintaining strict adherence to humane practices. These systems use computer vision technology to identify optimal cutting points, maximizing yield and minimizing waste. By controlling variables such as timing and handling with high accuracy, automated systems contribute to consistent meat grade outcomes.

Sensors continuously monitor quality parameters throughout the process, enabling real-time adjustments that preserve meat integrity. The consistent application of standardized procedures ensures uniformity in cuts and preparation, a crucial factor in achieving reliable meat grade classifications. This means customers receive products with reliable texture, flavor, and safety. The precision of automated systems also enhances traceability, allowing processors to document every step from farm to package. This technological advancement has simultaneously improved efficiency, product quality, and workplace safety, making it a cornerstone of modern meat processing.

The Impact of Precision Slaughtering

Precision slaughtering techniques have revolutionized the meat industry, introducing efficiency while maintaining ethical standards. The impact of these advanced methods extends far beyond mere production acceleration. Modern facilities utilize computer-guided systems that ensure consistency and accuracy in each processing step. Precision slaughtering impact goes beyond speed. It helps reduce errors that can damage the meat, such as bruising or contamination. When the process is smooth and carefully controlled, the meat retains its optimal quality, which benefits both producers and consumers. Additionally, these technologies support improved food safety by minimizing cross-contamination risks and enhancing traceability.

Workers also benefit from reduced physical strain as automated systems handle the most hazardous tasks. The environmental footprint of meat production likewise decreases through optimized resource utilization and reduced waste generation. As consumer awareness grows regarding ethical meat production, the adoption of precision slaughtering practices represents a significant step toward meeting both market demands and sustainability goals in the evolving food industry landscape.

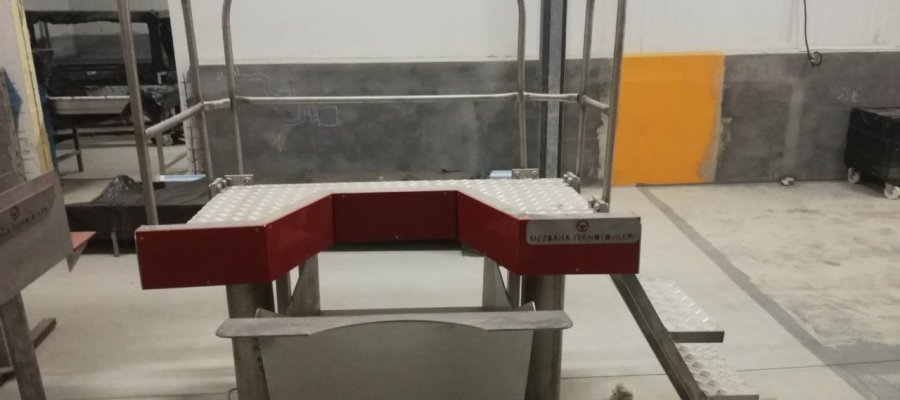

See also: cattle stunning box

Why Carcass Quality Factors Matter

Carcass quality factors — like fat distribution, muscle condition, and cleanliness — are all influenced by how the animal is processed. These elements significantly impact both the economic value and consumer acceptability of meat products. Proper fat distribution ensures optimal flavor and juiciness, while adequate muscle condition determines tenderness and texture. The meat industry recognizes that superior carcass quality translates directly to consumer satisfaction and repeat purchases. Additionally, these factors affect shelf life, cooking performance, and nutritional composition of the final product. Machines that follow strict hygiene standards and precise protocols support better meat quality after slaughter and help maintain high safety levels.

Modern processing facilities utilize advanced technology to ensure consistent carcass handling, minimizing contamination risks and preserving quality attributes. Regulatory agencies worldwide have established comprehensive grading systems based on these factors to standardize meat quality assessment. Ultimately, prioritizing carcass quality factors benefits the entire supply chain—from producers who receive premium prices to consumers who enjoy safe, high-quality.

See also: equipment for slaughterhouse