How Long Does It Take to Process One Animal with Modern Machines?

Modern machines process animals in 2-10 minutes, balancing speed, efficiency, and animal welfare in today’s meat industry.

13 June, 10:06

In today’s high-tech meat industry, efficiency and precision are more important than ever. But one common question remains: How long does it take to process one animal with modern machines?

The answer depends on various factors including automation level, facility size, and animal type. Let’s explore the typical meat processing time, and how slaughterhouse machine speed plays a role in both productivity and animal welfare.

Average Meat Processing Time with Automation

The meat processing industry has undergone revolutionary changes with technological innovation. Thanks to advancements in automated slaughter process systems, processing times have dramatically decreased. Modern facilities now operate with unprecedented efficiency while maintaining strict quality controls. A single cow in a fully modern facility can go from stunning to carcass splitting in about 7–10 minutes. This represents a significant improvement compared to traditional methods that could take up to 30 minutes per animal.

The integration of robotics and conveyor systems has streamlined every step of the process. For poultry, the process is even faster—typically under 2 minutes per bird. High-capacity facilities can process tens of thousands of birds daily with minimal human intervention. Automation has also improved consistency in cutting and portioning. These times reflect optimized workflows that balance speed with hygiene, safety, and animal processing duration standards. While maximizing throughput, facilities must still adhere to strict regulations regarding food safety, worker protection, and humane handling practices, demonstrating how automation serves multiple objectives simultaneously.

See also: foot washing machine

Slaughterhouse Machine Speed How Fast Is Too Fast?

Slaughterhouse machine speed can be astonishing. In modern meat processing facilities, the pace at which animals move through the system reflects our society's growing demand for affordable protein. Some high-capacity facilities can handle up to 400 pigs per hour or 12,000 chickens per hour. This industrial efficiency has transformed meat from luxury to everyday commodity, enabling unprecedented access to animal products. However, these remarkable speeds come with serious consequences. Workers face increased risks of injuries as they struggle to keep pace with rapidly moving lines. Additionally, animal welfare advocates argue that such velocity makes proper stunning and humane handling nearly impossible. While this boosts meat production efficiency, it also raises questions about worker safety and animal treatment. Regulatory agencies continually debate appropriate line speeds, balancing economic interests against ethical considerations.

Fast doesn't always mean better if humane handling is compromised. As consumers become more conscious about food production methods, the industry faces mounting pressure to find the sweet spot between productivity and responsibility.

Understanding Animal Processing Duration

The animal processing duration varies depending on species and the level of automation. For poultry, processing can be completed in as little as 2-3 hours from arrival to packaged product, while larger animals like cattle may require 24-48 hours including cooling periods. Manual or semi-automated processes naturally take longer, especially when special handling (like halal or kosher processing) is required. These specialized methods demand careful attention to ritual requirements and often involve skilled practitioners who perform specific cuts and procedures, extending processing times significantly. Modern facilities with high throughput objectives have invested heavily in technological solutions.

Automated systems aim to reduce this time while maintaining consistency. These sophisticated lines can process thousands of animals per hour while ensuring proper food safety protocols are followed. The balance between speed and welfare remains a critical consideration, as rushing any stage can compromise both product quality and humane treatment standards. Ultimately, processing duration represents a complex interplay between regulatory requirements, cultural practices, technological capabilities, and market demands.

See also: cattle stunning box

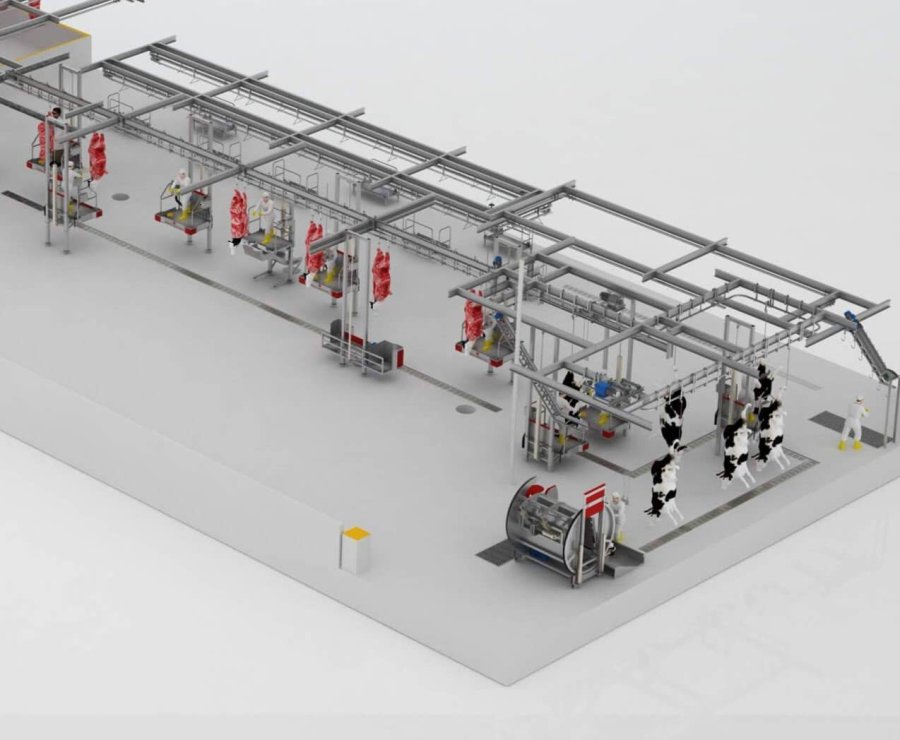

Automated Slaughter Process: Step-by-Step

The automated slaughter process represents a significant advancement in meat production technology, combining efficiency with standardized safety protocols. The process begins with stunning or anesthetizing the animal using electrical, mechanical, or gas methods to ensure humane treatment by rendering the animal unconscious before further processing. Following stunning, bleeding occurs where major blood vessels are severed, allowing for blood drainage which improves meat quality and extends shelf life. The next phase involves skinning or defeathering, where specialized machinery removes external coverings—hides from mammals or feathers from poultry—with remarkable precision and speed.

The process continues with evisceration, a critical step where internal organs are methodically removed to prevent contamination. Finally, carcass washing and splitting completes the procedure, with antimicrobial sprays sanitizing the carcass before it's divided into primary sections. Throughout this entire sequence, computer-controlled equipment maintains strict hygiene standards while maximizing production efficiency and consistency.

Meat Production Efficiency: Why It Matters

High meat production efficiency means more output with fewer resources. Modern facilities strive to optimize every stage of production while maintaining quality standards. Shorter processing times reduce operational costs and meet growing food demands. However, this must be balanced with ethical standards, including animal welfare and safe working conditions. As global protein needs increase, finding this balance becomes increasingly crucial for sustainable food systems.

See also: slaughtering tools and equipment