Latest Slaughterhouse Equipment 2025

Discover the latest slaughterhouse equipment 2025 with advanced automation, hygienic designs, energy efficiency, and sustainable meat processing solutions.

30 October, 09:10

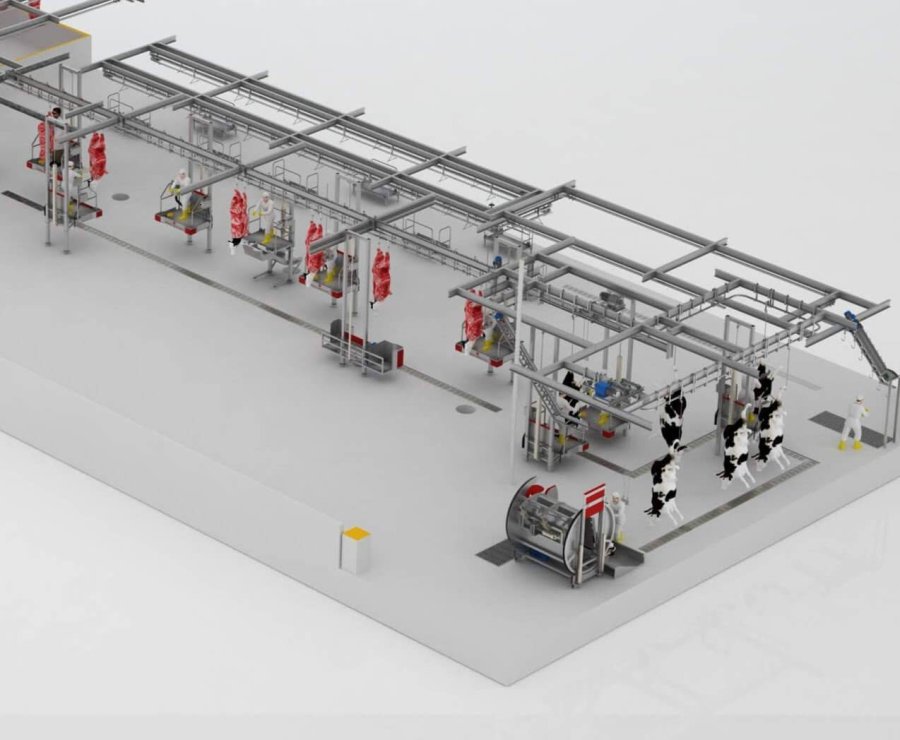

The meat processing industry is evolving at a rapid pace, and 2025 brings a new wave of innovations in slaughterhouse equipment. Modern slaughterhouses prioritize efficiency, safety, and sustainability, and the latest machinery reflects these demands. From automated processing lines to hygienic cutting tools, the newest equipment ensures higher productivity while maintaining strict compliance with health standards.

Automation and Efficiency in Modern Slaughterhouses

Automation remains the cornerstone of contemporary slaughterhouse operations. Advanced machinery, including automated stunning systems, cutting machines, and conveyer networks, minimizes human error and enhances speed. These technologies also help reduce labor costs, allowing facilities to allocate human resources to quality control and logistics management. Robotic meat processing units can now perform repetitive tasks with unmatched precision.

This innovation not only improves product consistency but also ensures that hygiene standards are maintained across all stages of processing. As a result, the integration of automation in slaughterhouses not only boosts efficiency but also addresses concerns related to animal welfare and food safety.

Hygiene and Food Safety Enhancements

In 2025, hygiene is more critical than ever. Equipment now incorporates stainless steel construction, antimicrobial surfaces, and easy-to-clean designs. Features like automated cleaning cycles, UV sterilization units, and sealed cutting chambers prevent contamination, making compliance with stringent food safety regulations seamless. Sanitation-focused innovations include drip-free slaughter lines and enclosed transport systems, which reduce the risk of cross-contamination.

These enhancements are designed to ensure that every step of the food processing journey prioritizes safety and cleanliness. For meat processors, these advancements are invaluable for maintaining high-quality products and minimizing the risk of recalls. By investing in cutting-edge hygiene technologies, the industry can ensure consumer trust and uphold public health standards.

Sustainability and Energy Efficiency

Sustainability is a key driver of equipment innovation. Modern slaughterhouse machines are designed to consume less energy, recycle water efficiently, and reduce waste. This commitment to sustainability not only meets regulatory requirements but also addresses consumer demand for more responsible practices in meat production. Energy-efficient refrigeration units and precision-controlled heating systems lower operational costs and environmental impact.

By optimizing energy use, facilities can significantly reduce their carbon footprint while maintaining high standards of food safety and quality. Some facilities have integrated waste-to-energy solutions, where by-products from meat processing are converted into biogas or fertilizer. This trend reflects the growing demand for eco-friendly and responsible meat production practices, showcasing the industry's commitment to sustainability and energy efficiency.

See also: slaughterhouse supplies

Specialized Cutting and Packaging Technologies

Advanced cutting equipment now allows for precision portioning, minimizing waste and maximizing yield. This technological evolution is crucial for industries looking to enhance efficiency while reducing costs. Implementing automated slicing, deboning, and packaging lines significantly reduces manual handling, which in turn improves both safety and productivity in the workplace. The advancements in packaging systems are equally impressive.

Innovations like vacuum-sealing and modified atmosphere packaging (MAP) technologies are designed to extend shelf life while maintaining product freshness, catering to the increasing consumer demand for quality. Additionally, the integration of smart sensors and IoT devices facilitates real-time monitoring of temperature, humidity, and machinery performance, ensuring optimal product quality and minimizing spoilage.

Key Advantages of Latest Slaughterhouse Equipment

The latest advancements in slaughterhouse equipment bring numerous key advantages that enhance operational efficiency and safety. Automation and robotics accelerate processing and reduce downtime, enabling facilities to meet increasing demand while maintaining high throughput. By incorporating these technologies, slaughterhouses can streamline workflows and improve overall productivity. Moreover, the integration of innovative machines leads to reduced human contact, which significantly minimizes workplace injuries and contamination risks. This not only protects workers but also ensures a safer environment for food processing.

Additionally, modern equipment is designed to be energy-efficient; innovative machines consume less power and optimize water usage, contributing to lower operational costs and environmental sustainability. Waste reduction and eco-friendly technologies promote responsible meat production practices, aligning with growing consumer demand for sustainable sourcing. Finally, advancements in technology enable precision cutting and packaging, which ensure consistent, high-quality products that meet market standards. These benefits collectively position slaughterhouses to operate more effectively in a competitive industry while prioritizing safety and sustainability.

See also: boot hangers