What Are Modern Slaughterhouse Systems?

Discover 2025’s advanced slaughterhouse systems, modern technologies, hygienic solutions, and setup guide for efficient meat processing.

23 July, 10:07

In recent years, the meat processing industry has undergone a major transformation. With growing global demand for efficiency, hygiene, and sustainability, modern slaughterhouse systems are no longer just about processing livestock—they’re about combining advanced engineering with animal welfare, food safety, and automation.

The Evolution of Slaughterhouse Systems

Traditionally, slaughterhouses were labor-intensive and posed numerous hygiene and safety challenges. Workers had to rely heavily on manual processes, which often led to inconsistencies and increased risks of contamination. The environments were not always optimized for animal welfare or worker safety, raising ethical concerns and operational inefficiencies. However, the rise of modern slaughterhouse technologies has changed the game. These advancements integrate automation, robotics, and smart monitoring tools to streamline the entire process.

Tasks such as stunning, bleeding, evisceration, and chilling are now performed with greater precision and efficiency. The incorporation of these technologies not only enhances productivity but also significantly improves hygiene standards and worker safety.

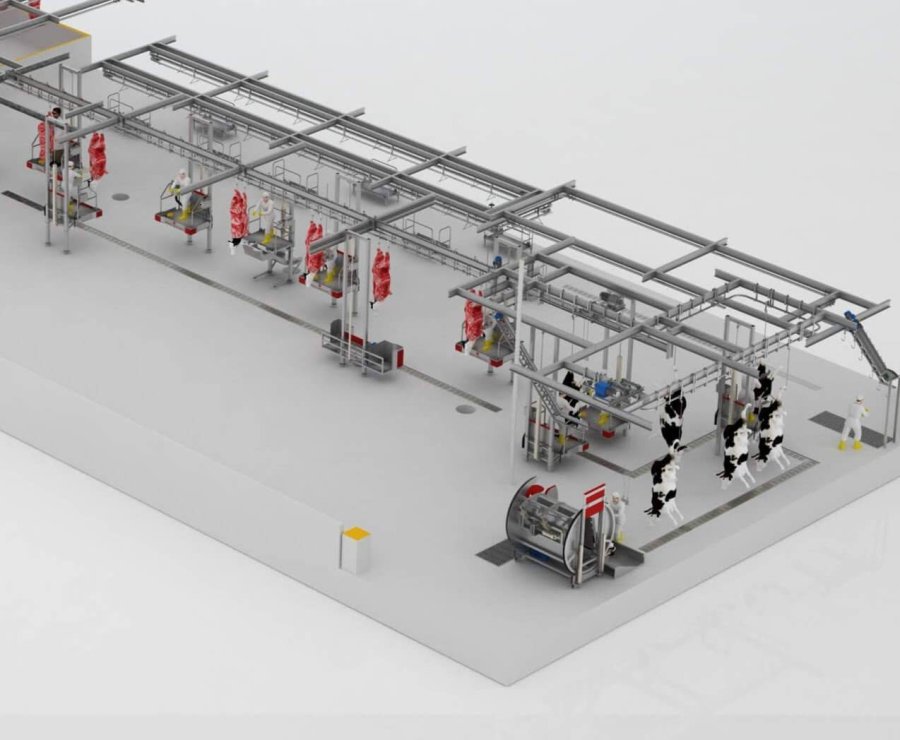

Automatic Slaughter Line

A cornerstone of modern facilities is the automatic slaughter line. These systems allow for high-speed, consistent processing with minimal human intervention, revolutionizing the meat processing industry. Designed for both small and large-scale operations, an automatic line reduces contamination risks and boosts productivity, ensuring a safer and more efficient workflow. Central to these systems are conveyor systems for carcass transport, which facilitate the seamless movement of animals through various stages of processing.

Additionally, automatic hide pullers and splitters enhance efficiency by quickly and effectively removing hides, while dehairing and decontamination units ensure that carcasses meet stringent hygiene standards. To further optimize operations, modern automatic slaughter lines are equipped with integrated data recording tools that track every aspect of the process.

Hygienic Slaughter Solutions

Hygiene is critical in any meat processing facility. That’s why hygienic slaughter solutions have become a major focus in recent years. Implementing advanced technologies and equipment is essential to ensure high standards of cleanliness. Stainless steel equipment for easy sanitation is now a standard choice, as it resists corrosion and can be thoroughly cleaned, reducing the risk of contamination. Furthermore, the introduction of touchless control panels minimizes human contact with surfaces, further enhancing hygiene protocols. These panels allow workers to operate machinery without direct contact, thereby reducing the potential for bacteria transfer. In addition to these innovations, water-saving cleaning systems have been developed to promote sustainability while maintaining hygiene.

These systems efficiently use water resources, ensuring that facilities can keep their environments clean without excessive water waste. Lastly, careful attention to airflow and drainage design to minimize bacteria spread is crucial in maintaining a healthy working environment.

See also: cattle stunning box

Slaughterhouse Setup Guide: Planning Your Facility in 2025

Planning a slaughterhouse requires careful attention to layout, equipment, legal standards, and environmental impact. The first step is site selection and ensuring zoning compliance to meet local regulations. This foundational work sets the stage for a facility that not only meets operational needs but also adheres to legal requirements. Once the site is established, the facility design must focus on efficient flow to streamline operations. An optimal layout minimizes bottlenecks and enhances productivity, ensuring that each stage of the process runs smoothly. Additionally, the selection of modern slaughterhouse systems is crucial for maintaining high standards of animal welfare and product quality. Incorporating energy-saving and waste-management features can significantly reduce the environmental footprint of the facility, promoting sustainability within the industry.

Key Features of Modern Slaughterhouse Systems

Modern slaughterhouse systems are designed with a strong focus on animal welfare, operational efficiency, and hygiene. Today’s systems integrate modern slaughterhouse technologies such as stunning chambers, automatic restrainers, and computerized monitoring tools. These systems not only streamline the production line but also help comply with strict international food safety regulations. One of the most transformative innovations in this field is the automatic slaughter line. This technology enables seamless movement of animals through each processing stage — from stunning and bleeding to skinning and evisceration — with minimal human intervention. This automation minimizes contamination risks and improves overall hygiene standards. Additionally, the use of real-time monitoring systems allows for immediate detection of any anomalies during the slaughter process, ensuring that both product quality and animal welfare are maintained.

Hygienic Slaughter Solutions for Safe Meat Processing

Setting up a new facility requires detailed planning to ensure that all aspects of the operation adhere to hygienic standards. This slaughterhouse setup guide helps investors and business owners navigate critical decisions essential for success. From land selection and design layout to choosing the right equipment, each choice impacts the overall efficiency and safety of meat processing. Compliance with national and global meat processing laws is crucial, as it safeguards public health and builds consumer trust.

In today's competitive market, investors are also looking into modular systems, which are designed to be scalable and allow for future expansion. These systems are particularly popular in regions where demand is growing rapidly, as they provide a flexible solution to meet increasing needs without compromising on hygiene.

See also: equipment for slaughterhouse