Increase Efficiency by 40% with Slaughterhouse Automation

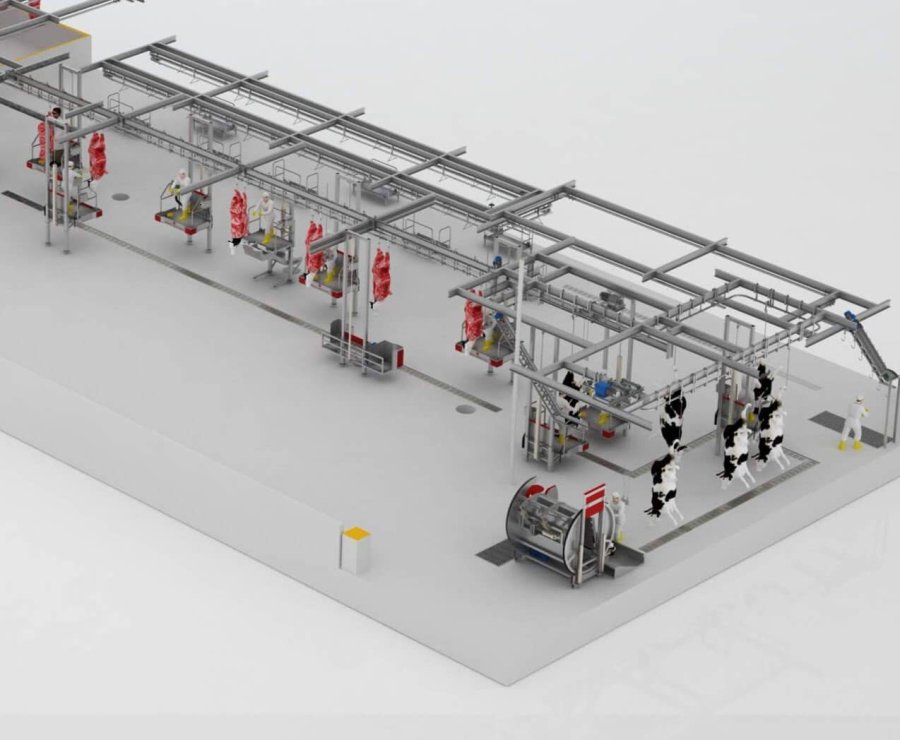

Boost productivity with slaughterhouse automation systems.

05 August, 17:08

In today’s fast-paced food industry, the demand for speed, safety, and sustainability has driven a major shift towards slaughterhouse automation systems. Automated technologies are no longer a luxury—they are a necessity for modern meat producers looking to scale operations, ensure compliance, and reduce costs. In this article, we explore how companies have increased efficiency by up to 40% through real-world implementations of efficient slaughter lines and meat processing technologies.

The Role of Automation in Modern Slaughterhouses

Slaughterhouse automation systems streamline the entire workflow—from live animal handling to carcass processing and packaging. These systems integrate robotics, sensors, and data analytics to reduce manual labor, minimize human error, and ensure consistency. By automating various stages of the slaughtering process, facilities can enhance efficiency and maintain high operational standards. One of the key benefits of automation is the ability to operate at high speed without compromising hygiene or quality standards.

The use of advanced automation systems allows for a more controlled environment, where conditions can be monitored in real-time, ensuring food safety. This capability is crucial in an industry where adherence to strict regulations is mandatory. By automating repetitive and high-risk tasks, businesses not only protect their workforce but also significantly reduce waste and improve yield. The implementation of Turkey slaughterhouse automation not only enhances productivity but also contributes to a more sustainable operation by minimizing the environmental impact associated with meat production. Overall, automation is transforming the slaughterhouse industry, making it safer, more efficient, and more reliable.

European Facility Cuts Costs by 35%

A leading slaughterhouse in Northern Europe implemented a fully automated production line digitalization platform in 2024. This advanced system included real-time data collection, robotic cutting systems, and AI-driven quality control, revolutionizing the facility's operational processes. Within just six months of implementation, the facility reported a remarkable 40% increase in operational efficiency and a significant 35% reduction in labor costs. The integration of efficient slaughter lines allowed the company to scale up output without the need to expand its workforce, demonstrating the power of automation in enhancing productivity.

Moreover, the facility benefited from enhanced traceability throughout the production chain, ensuring higher standards of quality and compliance. To further optimize operations, the use of predictive maintenance algorithms played a crucial role, reducing machine downtime by 25%. This proactive approach not only minimized disruptions but also led to additional cost savings, solidifying the facility's position as a leader in the industry.

Be sure to take a look at our carcass splitting saw article as well

Middle Eastern Plant Adopts New Meat Processing Technologies

Another success story comes from a mid-sized processing plant in the Middle East, which upgraded its facility using advanced meat processing technologies. The modernization involved vacuum stunning systems, automated evisceration, and high-speed deboning units—all controlled through a centralized software interface. This strategic investment allowed the plant to enhance its operational efficiency significantly.

The implementation of these cutting-edge technologies not only boosted production speed but also improved animal welfare, addressing rising consumer concerns and ethical standards. By adhering to stringent protocols, the plant successfully met international export standards, positioning itself as a reliable supplier in a competitive marketplace.

Benefits of Production Line Digitalization

Production line digitalization plays a crucial role in achieving transparency and efficiency within the manufacturing sector. By integrating advanced technologies such as sensors and software, companies can monitor each stage of the slaughtering process with unparalleled precision. This real-time data collection allows managers to gain insights into critical metrics, enhancing operational decision-making. For instance, tracking Yield rates enables firms to optimize their resources and reduce waste, ultimately improving profitability. In addition to yield optimization, downtime tracking is another significant benefit of production line digitalization. By identifying periods of inactivity, managers can swiftly address issues, minimizing production delays and ensuring a smoother workflow.

Furthermore, monitoring equipment performance through digital tools helps in proactive maintenance, reducing the risk of unexpected breakdowns and increasing overall productivity. Hygiene audit compliance becomes more manageable with digitalization, as automated systems can continuously check for adherence to safety standards. This not only safeguards product quality but also builds consumer trust. Overall, the digital transformation of production lines is essential for modernizing operations and driving sustainable growth in the industry.

Why Modernization Is the Future

Slaughterhouse modernization isn’t just about adding machines—it’s about transforming your operational mindset. The landscape of food production is rapidly changing, driven by consumer demand for transparency and ethical practices. As awareness around sustainability and food safety increases, producers must adapt or risk falling behind in a competitive market. Modern facilities equipped with slaughterhouse automation systems are better positioned to meet regulatory standards and consumer expectations.

These advanced systems allow for greater efficiency and precision, minimizing waste and ensuring that products are safe for consumption. By investing in modernization, producers can streamline their operations, ultimately leading to a more sustainable business model. Furthermore, modernization enables the scaling of production without sacrificing quality or safety. As global populations rise and demand for meat products increases, the need for efficient and responsible production methods becomes paramount.

Make sure to check out our equipment for slaughterhouse content too