Slaughterhouse Setup Cost 2025: Step-by-Step Guide

Discover 2025 slaughterhouse setup cost, construction prices & ROI. A complete guide to meat processing plant investment & cost-saving tips.

05 August, 17:08

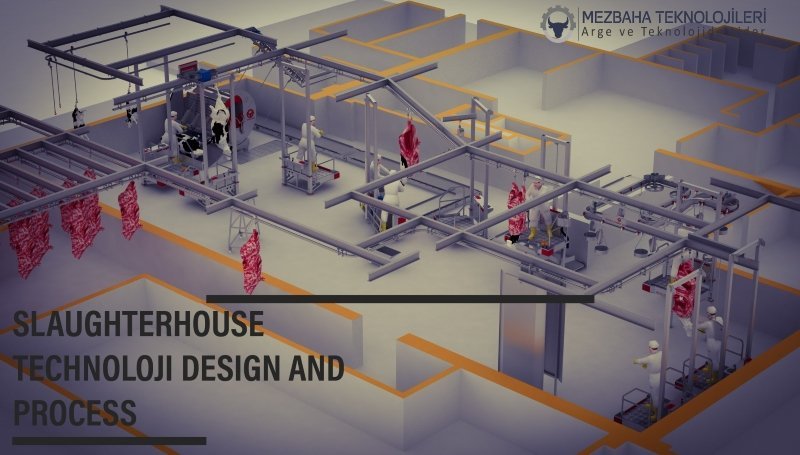

Setting up a slaughterhouse in 2025 requires careful planning, regulatory compliance, and an understanding of both initial capital investment and long-term profitability. Whether you’re planning a facility for cattle, poultry, or small ruminants, knowing the slaughterhouse setup cost, understanding current slaughterhouse construction prices, and forecasting your return on investment are crucial first steps.

Define the Scope and Type of Slaughterhouse

Defining the scope and type of a slaughterhouse is crucial for ensuring efficiency and compliance with health regulations. A small ruminant slaughterhouse, designed specifically for animals like sheep and goats, typically requires less space and simpler technology compared to larger facilities. These establishments focus on maintaining high hygiene standards while accommodating the unique needs of these animals. On the other hand, a poultry slaughterhouse is tailored for processing birds, demanding specialized equipment to handle the fast-paced nature of poultry processing.

This type of slaughterhouse often involves advanced automation to enhance efficiency and reduce labor costs. In contrast, a large animal facility caters to larger livestock such as cattle and buffalo, necessitating significant infrastructure investment due to the size and weight of the animals involved. These facilities have rigorous hygiene protocols to prevent contamination and ensure meat quality.

Site Selection and Regulatory Approvals

Location impacts not only logistics and access to livestock but also construction costs. Choosing a site in rural or semi-urban areas often leads to benefits such as lower land prices and fewer zoning complications. This can significantly reduce the initial investment required for establishing a facility. However, the selection process must consider more than just financial aspects; regulatory compliance is essential. No matter the location, you’ll need to comply with local and national animal welfare regulations.

These regulations ensure humane treatment and care of animals, which is crucial for any livestock operation. Additionally, adherence to wastewater treatment standards is necessary to prevent environmental contamination, safeguarding both the ecosystem and public health. Moreover, obtaining environmental clearance and hygiene certifications is integral to the site selection process. These approvals not only facilitate smoother operations but also build trust with consumers and regulatory bodies.

Make sure to check out our automated slaughterhouse content too.

Estimating Slaughterhouse Construction Prices (2025)

Estimating slaughterhouse construction prices for 2025 reveals significant variations influenced by several factors. The slaughterhouse construction prices vary widely based on location, capacity, and level of automation. Understanding these elements is crucial for accurate budgeting and planning in the meat processing industry. Below are average 2025 estimates that reflect these differences, providing stakeholders with valuable insights for investment decisions.

|

Facility Type |

Estimated Construction Cost (USD) |

|

Basic small ruminant slaughterhouse |

$100,000 – $250,000 |

|

Semi-automated poultry unit |

$300,000 – $500,000 |

|

Fully automated cattle unit |

$1M – $3M |

|

Mixed slaughterhouse (medium-scale) |

$600,000 – $1.2M |

Equipment and Technology

Slaughterhouses today increasingly rely on automation for hygiene, speed, and consistency, allowing them to meet the demands of modern meat production efficiently. When planning your meat processing plant investment, it is essential to include vital equipment such as stunning and bleeding systems, which are crucial for humane animal treatment and effective processing. These systems ensure that the initial stages of meat production are handled swiftly and ethically, setting a standard for the entire operation. Additionally, the inclusion of skinning and evisceration equipment is necessary to streamline the processing of carcasses, minimizing labor costs while maximizing efficiency. After processing, maintaining product quality relies on sophisticated cold storage and chilling systems that prevent spoilage and ensure safety.

Furthermore, conveyor belts and transport lines facilitate the smooth movement of products through various stages, enhancing productivity across the facility. To ensure a sustainable operation, waste management systems must also be incorporated to handle by-products responsibly. The total cost of equipment can range from $50,000 to $2 million, depending on the size of the plant and the level of automation implemented.

Be sure to take a look at our equipment for slaughterhouse article as well.

Operational Costs and Staffing

Operational costs and staffing are crucial considerations for any medium-scale plant, typically averaging between $20,000 to $70,000 monthly. A significant portion of these expenses is attributed to skilled labor and training, which ensures that employees are equipped with the necessary expertise to operate machinery and maintain product quality. Investing in continuous training can enhance productivity and reduce errors, ultimately contributing to cost efficiency. Furthermore, essential services such as utilities, including water, electricity, and refrigeration, represent a substantial part of the operational budget. Effective management of these resources is vital to maintaining a conducive working environment and ensuring product integrity.

Additionally, the procurement of cleaning and sanitation supplies is necessary to adhere to health regulations and uphold high standards of hygiene. The logistics involved in packaging and cold chain logistics also incur costs that must be accounted for, as they are essential in preserving the quality of perishable goods.

Calculating Return on Investment (ROI)

Calculating Return on Investment (ROI) involves assessing the financial viability of a meat processing operation. For instance, with a daily slaughtering capacity of 100 sheep/day, it's essential to consider the market price of processed meat alongside revenues from by-product sales such as hide, blood, and bones. Additionally, understanding local demand and competition can significantly influence profitability.

Typically, the payback period for small to medium units ranges from 2 to 4 years, making it crucial to project cash flows accurately for informed investment decisions.

You might also be interested in our cattle stunner piece.