Tips for Fast and Hygienic Cutting with a Brisket Saw

Discover expert tips for fast, precise, and hygienic brisket cutting using the right brisket saw in modern meat processing facilities.

08 January, 07:01

Speed and hygiene are no longer competing priorities in modern meat processing. With rising production volumes, stricter food safety regulations, and increasing customer expectations, the way brisket is cut has become a strategic operation rather than a simple mechanical task. At the center of this evolution stands the brisket saw—a tool that defines efficiency, precision, and cleanliness when used correctly.

Why Brisket Cutting Requires a Specialized Approach

Brisket is structurally complex. This complexity arises from dense connective tissues and varying grain, so cutting requires awareness of fiber direction and anatomy rather than brute force. Dense muscle fibers, variable fat distribution, and thickness differences demand a cutting solution that offers both control and consistency. Without that control, operators struggle to follow the natural seams, resulting in inconsistent portioning and wasted yield.

Traditional cutting tools often fail to deliver uniform results, leading to product loss due to uneven cuts, increased handling time, and Higher contamination risks as more manual trimming and repositioning invite touchpoints. In contrast, a properly selected brisket saw eliminates these challenges by providing stable cutting motion, predictable blade performance, and reduced operator fatigue. Choosing the right equipment improves yield, speeds throughput, and promotes food safety, making a specialized approach essential for consistent commercial brisket processing.

Engineering Matters: Choosing the Right Brisket Saw

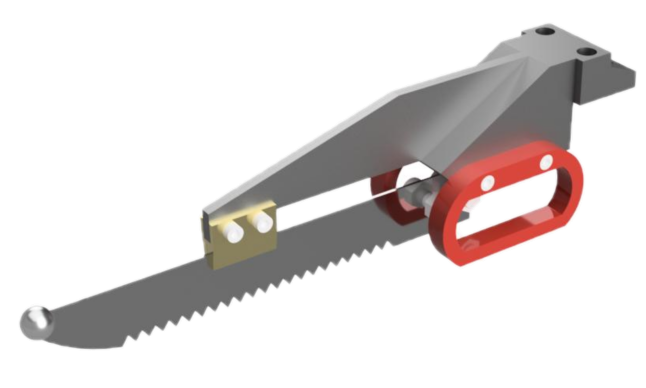

Choosing the right equipment matters because not all saws are created equal. In a brisket saw meat plant, small differences in design and durability add up quickly, and In industrial settings, the difference between average and optimized equipment can be measured in tons per day. Managers who prioritize throughput and product integrity invest in machines that reduce waste and speed cycles.

Key design elements include blade tension stability to prevent micro-fragmentation and motor torque consistency for uninterrupted cuts, which together ensure clean, repeatable separations without stressing tissue or blade components. Those factors lower rework and trim losses while keeping operators safe.

Stainless steel housing to withstand aggressive sanitation cycles is essential, because these features are especially critical in a brisket saw meat plant, where downtime or contamination can affect entire production lines. Investing in optimized saws pays back in uptime, food safety, and predictable output.

Speed Without Sacrificing Control

In modern processing, fast cutting does not mean aggressive cutting. Operators often believe brute force creates speed, but one of the most common misconceptions in meat processing is that speed comes from operator force. Well-designed systems prove the opposite: In reality, speed is achieved through mechanical harmony. When blades, guides and feed systems work in concert, efficiency rises without compromising product quality, so operators can maintain pace while reducing fatigue and error. The outcomes are clear — Cuts remain clean because alignment and timing prevent ragged edges; Muscle fibers stay intact, preserving texture and bite; and delicate layers are protected so fat layers are preserved without smearing, keeping appearance and mouthfeel optimal. Together, these principles show that true speed in processing is precision-driven, not force-driven, delivering consistent output and superior product integrity.

Hygienic Brisket Cutting: Beyond Surface Cleanliness

True hygienic brisket cutting goes far beyond washing down equipment at the end of the shift. It starts with design and continues with daily operational discipline. Achieving this requires specifying and installing equipment that supports sanitation-forward workflows, training staff to recognize contamination risks, and documenting cleaning schedules. When machinery allows tool-less disassembly for rapid cleaning, teams can access food contact surfaces quickly, reducing downtime and the window for bacterial growth.

Choosing components with a minimal crevice design to prevent bacterial buildup further limits harborage sites and simplifies inspection, while implementing food-grade lubrication systems prevents lubricant migration into product and removes a common contamination source. Together these elements create a layered defensive approach: hygienic design, practical features, and disciplined daily practice that ensure brisket cutting remains safe from live production through final packaging.

Workflow Optimization Inside High-Volume Facilities

In a brisket saw meat plant, cutting is never an isolated task. It is part of a tightly connected workflow involving trimming, portioning, packaging, and cold storage. To reduce waste and delays, position the brisket saw to minimize product transport distance, which shortens handling time and lowers temperature excursions between stations. Process mapping and synchronized schedules help ensure that cutting steps feed evenly into downstream operations. Equally important is throughput matching: Align cutting speed with downstream packaging capacity so buffers do not build and refrigeration load remains steady.

Ongoing skills development and visual checks matter — Train operators to recognize blade wear before quality drops — preserving cut accuracy and reducing rework. Together these measures create a responsive, low-loss production system suited to high-volume facilities.