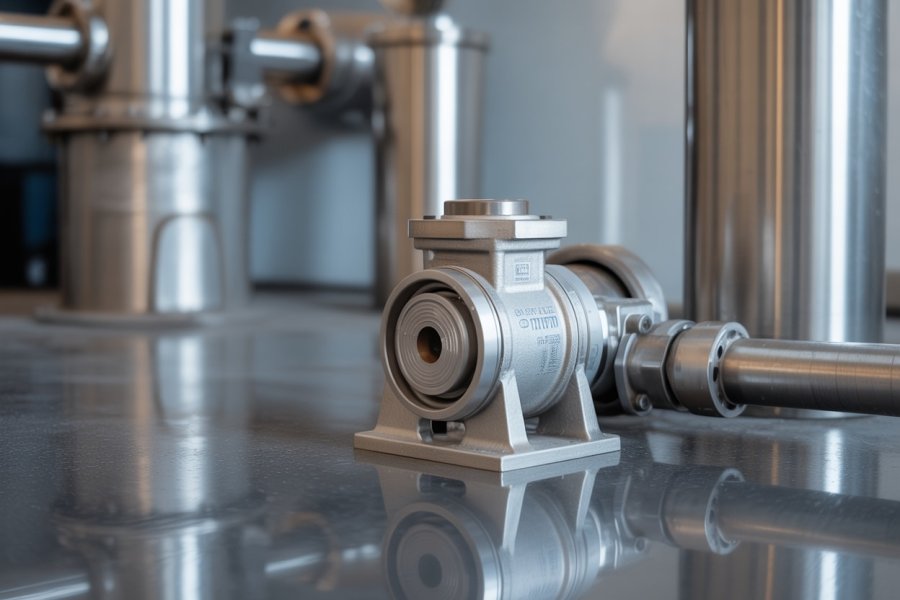

Tripe Waste Pumps Hygienic Cost Effective

Hygienic and cost-effective tripe waste pump solutions improve slaughterhouse efficiency, ensure safe waste transfer, and support modern tripe handling systems.

25 December, 12:12

In modern meat processing facilities, efficiency alone is no longer enough. Hygiene standards, environmental responsibility, and operational cost control have become equally critical. This is where tripe waste pump solutions play a transformative role. Designed specifically for handling complex organic waste streams, these pumps offer slaughterhouses a smarter, cleaner, and more sustainable way to manage by-products.

Understanding the Nature of Tripe Waste in Meat Processing

Tripe waste is one of the most demanding by-products in slaughterhouse operations. Derived from the stomach linings of cattle, sheep, and other livestock, this material presents unique handling challenges in meat processing facilities. It contains semi-solid organic matter, fluids, fibers, and residues that can easily clog standard equipment. The complex composition includes partially digested feed, gastric fluids, mucous membranes, and connective tissue fragments, all of which vary in viscosity and density. Mishandling this waste not only leads to hygiene risks but also causes downtime and high maintenance costs.

A properly engineered slaughterhouse waste pump is designed to cope with these conditions by ensuring smooth, continuous transfer without manual intervention. These specialized pumps feature enlarged impellers, hardened components, and self-cleaning mechanisms that prevent blockages and minimize wear. This directly improves sanitation while reducing labor dependency in sensitive processing zones. By automating the waste removal process, facilities can maintain stricter hygiene standards and allocate human resources to more critical production tasks.

Why Standard Pumps Fail in Tripe Applications

Traditional centrifugal or basic displacement pumps are not suitable for tripe waste. The reasons are structural rather than operational. Inconsistent viscosity of tripe content causes standard pumps to lose efficiency as they cannot adapt to rapidly changing fluid properties. The presence of fibrous and fatty materials creates mechanical stress on impellers and seals designed for uniform liquids. Furthermore, the high bacterial load requiring sealed systems makes conventional pumps inadequate, as their standard sealing mechanisms cannot prevent contamination or contain odors effectively.

Frequent blockages causing production stoppages represent the most critical failure point, resulting in costly downtime and maintenance. A purpose-built tripe waste pump addresses these issues through reinforced internal geometry, controlled flow mechanisms, and materials suitable for aggressive organic media. These specialized pumps feature wider flow passages, hardened components, and enhanced sealing systems specifically engineered to handle the unique challenges of tripe waste processing reliably.

The Role of Tripe Handling System Integration

A pump alone is not enough. To achieve real efficiency, it must function as part of a fully integrated tripe handling system. This system connects washing units, separation tanks, waste transport lines, and treatment or disposal points into one hygienic workflow. Modern meat processing facilities require comprehensive solutions that address every stage of tripe waste management, from initial collection through final disposal. The integration of specialized equipment creates a seamless operation that maximizes productivity while maintaining the highest sanitation standards.

When properly integrated, a tripe handling system eliminates open handling of waste, reduces cross-contamination risk, and ensures compliance with international food safety standards such as HACCP and ISO 22000. This closed-loop approach protects workers from exposure to harmful pathogens, prevents environmental contamination, and maintains product integrity throughout the processing facility. Automated systems also reduce labor costs and human error while providing consistent, reliable performance that manual handling cannot match.

Hygienic Design Principles That Matter

Hygiene is not just about cleaning; it is about preventing contamination from the start. Modern tripe waste pump designs follow strict hygienic engineering principles:

-

Smooth internal surfaces to prevent residue buildup

-

Fully enclosed transfer to eliminate exposure

-

Easy clean-in-place (CIP) compatibility

-

Corrosion-resistant materials suitable for organic acids

Cost Efficiency Beyond the Purchase Price

Cost effectiveness is often misunderstood as low upfront investment. In reality, the true value of a tripe waste pump lies in long-term operational savings that extend far beyond the initial purchase price. Organizations that focus solely on acquisition costs frequently overlook the substantial financial impact of ongoing expenses. A properly selected pumping system delivers multiple economic advantages, including reduced maintenance frequency, minimal production interruptions, lower water and chemical usage during cleaning, and decreased labor costs through automation.

These factors compound over the equipment's lifespan, creating significant cost reductions that dwarf the initial investment differential. When evaluated over time, a well-designed tripe handling system delivers measurable financial benefits while improving overall plant reliability. Smart procurement decisions consider total cost of ownership rather than just the purchase price, ensuring optimal returns on capital investments.

Environmental and Sustainability Advantages

Sustainability is becoming a strategic priority in meat processing. Efficient waste transfer directly supports environmental goals by minimizing leakage, odor emissions, and uncontrolled discharge.

A modern slaughterhouse waste pump helps facilities:

-

Improve waste segregation for recycling or rendering

-

Reduce wastewater contamination load

-

Support compliance with environmental regulations

-

Optimize downstream waste treatment efficiency