What Are the Most Common Machines Used in Cattle Slaughter?

Common cattle slaughter equipment and beef processing machinery streamline the meat industry with efficiency and animal welfare in mind.

13 June, 10:06

If you’ve ever wondered how a large beef processing plant operates so efficiently, it’s all thanks to a range of specialized machines designed specifically for cattle slaughter.

Whether you’re working in the meat industry or simply curious about how your steak makes it from farm to table, understanding the common slaughterhouse machines and cattle slaughter equipment can give you a clearer picture of this complex process.

Why Machinery Matters in Modern Cattle Slaughter

The meat industry relies heavily on automation and machinery to process cattle efficiently and humanely. Modern slaughterhouses utilize specialized equipment like captive bolt stunners and pneumatic knockers for humane stunning before processing begins. After stunning, animals are hoisted onto a processing line where hydraulic hide pullers and automated skinning machines remove hides with precision. The carcass then moves to splitting saws—powerful band or circular saws that divide the carcass along the spine. Further along the line, beef processing machinery includes evisceration equipment that carefully removes internal organs under strict hygiene protocols. Automated washing cabinets sanitize carcasses using high-pressure water systems.

In cutting rooms, band saws, de-boning conveyor systems, and vacuum packing machines prepare final products for distribution. These bovine slaughter tools ensure consistency and quality while maintaining strict food safety standards. Modern slaughterhouse designs integrate these machines into ergonomic workflows that prioritize both worker safety and animal welfare while maximizing operational efficiency.

Key Cattle Slaughter Equipment You Should Know

Stunning Devices

Animal processing facilities employ stunning equipment to ensure ethical treatment during meat production. The process begins with stunning equipment that humanely renders the animal unconscious before slaughter. Modern devices utilize electrical current or mechanical methods, adhering to strict regulations. This is a crucial step that prioritizes animal welfare and prepares the cattle for the next stages while maintaining meat quality and worker safety.

Bleeding and Hoisting Machines

After stunning, bleeding tables and hoisting systems are essential components in meat processing facilities. They facilitate rapid exsanguination while maintaining sanitary conditions. These machines are designed to handle heavy loads safely and hygienically, allowing workers to efficiently process carcasses without contamination. The integration of automated bleeding tables and hoisting systems has revolutionized slaughterhouse operations, increasing throughput while ensuring animal welfare standards are maintained throughout the bleeding process.

Skinning and Dehiding Equipment

Removing the hide is a delicate task that requires precise beef processing machinery. The initial incisions must be carefully executed to maintain meat quality during the dehiding process. Modern slaughterhouses utilize hydraulic hide pullers and pneumatic knives to ensure efficiency. Automated skinning machines improve consistency while handling various cattle sizes. Automated skinning machines reduce manual labor and speed up the process while minimizing contamination risks. These systems incorporate sanitizing features that maintain food safety standards throughout the entire operation.

Evisceration Tools

Bovine slaughter tools include evisceration machines that efficiently separate internal organs from carcasses during processing. This step is essential for maintaining the quality and safety of the meat, preventing contamination and allowing for proper inspection. Modern evisceration machines that help remove internal organs quickly and cleanly have revolutionized meat processing facilities, improving throughput while ensuring hygienic standards are met.

See also: Turkey slaugterhouse

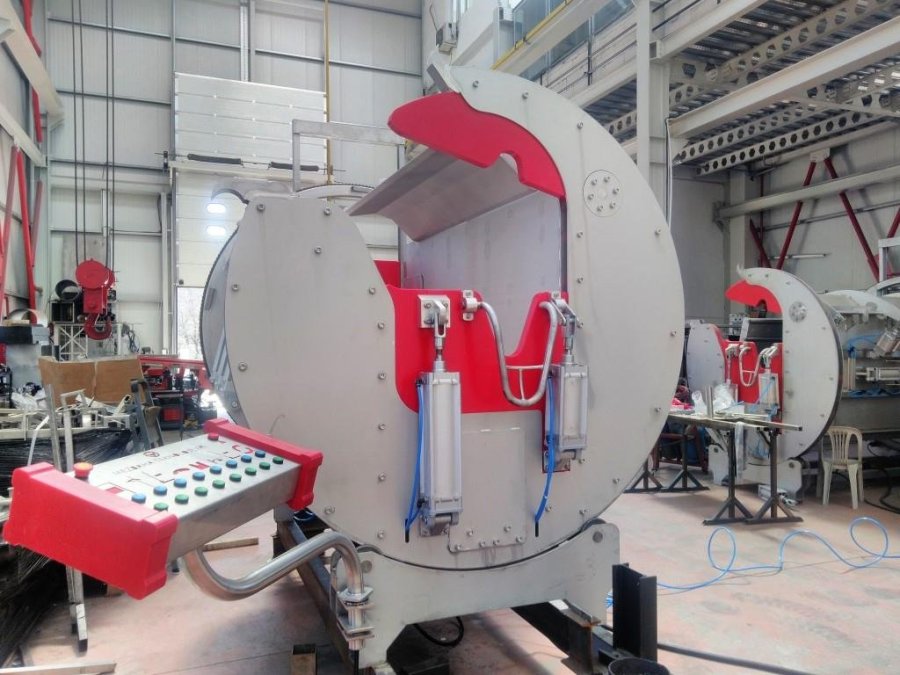

Carcass Splitting and Washing Machines

Once the carcass is prepared, it enters the processing line where hydraulic splitting saws precisely divide it along the spine into symmetrical halves. These powerful machines ensure consistent cuts while maintaining product integrity. Next, automated washing equipment thoroughly rinses the split sections, removing bone fragments and contaminants. This critical sanitation step ensures the meat is properly divided and cleaned before further processing or packaging, meeting strict hygiene standards.

How Common Slaughterhouse Machines Improve Efficiency

Using specialized cattle slaughter equipment streamlines the entire process from start to finish. Modern slaughterhouses implement conveyor systems and hydraulic restrainers that significantly increase throughput while maintaining humane practices. With automation, facilities can process more animals in less time without compromising on hygiene or safety standards. Computerized stunning systems ensure consistent application while reducing worker fatigue and injury. This efficiency not only meets growing demand in the meat industry but also helps reduce costs through labor optimization and improved yield recovery, allowing companies to remain competitive in global markets.